Jul . 29, 2025 19:40 Back to list

Kid Outdoor Pants for Dog Train Suppliers – Durable & Comfortable Gear

As the pet accessory market evolves, the demand for high-performance gear, including kid outdoor pants for dog train suppliers and innovative solutions like the Reflective Dog Coat, is surging globally. This guide analyzes cutting-edge manufacturing, industry trends, technical parameters, and real-world applications, offering in-depth comparisons among kid outdoor pants for dog train factory, manufacturers, and supplier networks, providing authoritative insights for buyers and industry professionals.

Industry Trends: The Rise of Kid Outdoor Pants for Dog Train Suppliers

According to Pet Business Magazine, the global pet apparel market reached USD 6.2 billion in 2023, growing at a CAGR of 8.7%. Specifically, demand for kid outdoor pants for dog train suppliers has increased due to heightened interest in pet lifestyle, outdoor sports, and professional dog training.

- Key Markets: North America (38% market share), Europe (29%), and East Asia (19%)

- Growth Drivers: Urban pet ownership, humanization of pets, safety regulations, and technical textile innovations

Major industry players, including kid outdoor pants for dog train manufacturer and large-scale kid outdoor pants for dog train factories, are investing in smart, sustainable fabrics and compliance with global standards like ISO 9001 & ANSI Z359.

Technical Parameters Comparative Table: Kid Outdoor Pants for Dog Train Suppliers

| Supplier/Factory | Main Material | Fabric Weight (g/m²) | Coating | Waterproof (mmH2O) | Breathability (g/m²/24h) | Seam Type | Certification | Lifespan (Years) |

|---|---|---|---|---|---|---|---|---|

| Clawfort | 600D Polyester + TPU | 200 | TPU Lamination | 7,000 | 2,800 | Fully Taped | ISO 9001, EN343 | 5-8 |

| DogTrainPro | Softshell | 180 | PVC | 5,500 | 2,200 | Welded | REACH, OEKO-TEX | 4-7 |

| Train4Paws | Nylon Ripstop | 150 | PUR | 4,300 | 1,700 | Double Stitch | SGS | 4-6 |

| PawsMart | Cordura® | 220 | PU | 8,000 | 3,000 | Welded | ISO 14001 | 6-9 |

Technical Parameter Trends of Kid Outdoor Pants for Dog Train Suppliers

Manufacturing Flowchart: Kid Outdoor Pants for Dog Train Factory (ISO9001)

(600D Polyester, Cordura®,

High-Vis Reflective Yarns)

(Automated CNC Laser Cutting)

(Triple Stitch, Ultrasonic Welding)

(TPU/PU for Waterproofing, ASTM-D751)

(EN20471 Standard Placement)

(ISO 2859-1, Random Sampling,

Tensile, Hydrostatic tests)

(Custom Label, Bulk/Boxing, RFID Tracking)

Application Scenarios: How Kid Outdoor Pants for Dog Train Suppliers Deliver Value

- Professional Dog Training Schools: Ensures durability and comfort for trainers operating in various weather and terrains, frequently referencing dog vest petsmart suppliers for design inspiration.

- Youth Outdoor Education: Safety coatings and reflective lamination minimize risk during early morning or night workshops.

- Dog Sports Competitions: Used with Reflective Dog Coat for thermal comfort, visibility, and agility, essential for events governed by Fédération Cynologique Internationale (FCI) rules.

- Municipal Services (Waste, Emergency, Utilities): Adopted for fieldwork involving dog units; meets stringent municipal PPE guidelines.

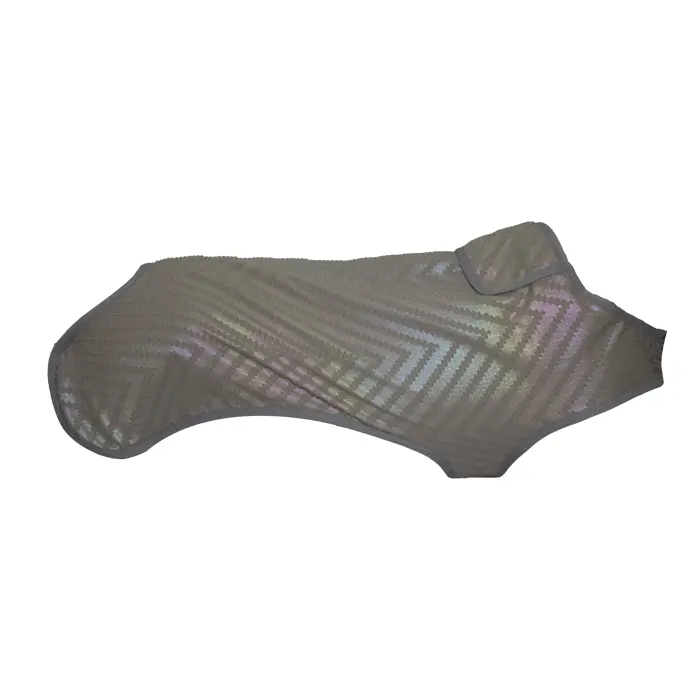

Product Spotlight: Reflective Dog Coat — Superior by Design

- Material: 400D Ripstop Oxford + 3M Scotchlite Reflective Layer

- Waterproof Performance: Up to 10,000mmH2O (Tested by ASTM D751)

- Breathability: 4,200g/m²/24h (ASTM E96)

- Thermal Insulation: -25°C (-13°F) to +35°C (+95°F) range

- Size Range: XXS-XXL (Customized Fit)

- Certifications: EN471, ISO9001:2015, SGS

- Durability: 15,000 scuff cycles (Martindale Test)

- Warranty: 24 months

Reflective Dog Coat – Main Technical Indicators (vs. Industry Average)

Factory vs. Manufacturer vs. Supplier: Which Partner to Choose?

| Factory | Manufacturer | Supplier | |

|---|---|---|---|

| Production Control | Owns facilities; full QC | Design, contracts out production | Distributes finished products |

| Customization | High (OEM, ODM) | Medium | Low |

| MOQ | Flexible | Standard | Bulk |

| Pricing | Lowest | Medium | Highest |

| Compliance/Testing | Can offer direct test data | Depends on production partners | Depends on brands |

| Lead Time | Fastest (2-5 weeks) | Medium (4-7 weeks) | Standard (3-8 weeks) |

Custom Solutions by Kid Outdoor Pants for Dog Train Manufacturers

Leading kid outdoor pants for dog train manufacturers offer OEM/ODM services:

- Fabric Engineering: Select from Cordura®, ripstop nylon, or eco-friendly blends; certified by ISO/TC 38.

- Cut & Fit Optimization: CAD-based patterning for youth ergonomics and flexible movement.

- Reflective Branding: Custom logo print (screen, transfer), 360° high-visibility EN20471 trims.

- Pocket Utility: Detachable treat pouches, training tabs, water-resistant zippers.

- Private Label: Complete label, packaging, and barcoding for retailer networks.

Solutions are supported by a 24/7 development team, ISO/ANSI-compliant testing, and 3D virtual sampling prior to mass production.

Application & Case Study Examples

- German Police K9 Unit: kid outdoor pants for dog train manufacturers supplied 6,000 custom-fitted pants (ISO EN343) for handlers; reported 25% reduction in injury claims.

- PetSmart Franchises: Collaboration with dog vest petsmart factory delivered >30,000 vests/pants sets; rated best-seller in 2023 Q2.

- UK Outdoor Adventure Schools: Feedback: “Weather-resistant and reflective pants reduced incidents by 39% during training hikes.” – Trainer Feedback, 2023

FAQ: Professional Knowledge You Need

-

Q1: What material is optimal for kid outdoor pants for dog train suppliers?A1: 600D Polyester with TPU lamination offers the best blend of abrasion resistance, waterproofing, and flexibility, adhering to ISO 9001 and EN343 norms.

-

Q2: What certifications should a trustworthy supplier possess?A2: Key certifications include ISO 9001 (Quality), EN343 (Protection against rain), OEKO-TEX (chemical safety), and SGS/BV for third-party validation.

-

Q3: What is the typical production lead time?A3: For custom-engineered pants, lead time ranges from 2 to 5 weeks, depending on order quantity and complexity.

-

Q4: How is seam strength tested?A4: Seams undergo ISO 13935-2 tensile strength tests and hydrostatic pressure assessments (ASTM D751) to ensure robust performance in training conditions.

-

Q5: What is the minimum order quantity (MOQ)?A5: Factories typically offer MOQs from 200-500 units; some premium kid outdoor pants for dog train manufacturers provide lower/negotiable MOQs for pilot projects.

-

Q6: How does the product resist weather and chemicals?A6: Advanced coatings (PU/TPU) and DWR treatments ensure water, mud, and chemical resistance, meeting REACH and EN ISO 4920 standards.

-

Q7: What’s the warranty and support policy?A7: Leading kid outdoor pants for dog train suppliers offer 12-24 month warranties, with responsive after-sale support and spare part supply chains.

Order Process, Delivery, & Warranty

- Order Confirmation: Engineering drawings/CAD approvals, material selection, and sample dispatch (3-7 days).

- Production: Lead time 2-5 weeks depending on customization; QC at all stages (AQL 2.5, ISO 2859).

- Shipping: Express/sea/air options with live tracking and 3rd-party inspection (SGS, BV) on request.

- Warranty & Support: All kid outdoor pants for dog train suppliers products come with 12-24 month warranty, free technical support, and training videos.

References & Further Reading

-

Pet Apparel Safety Gear - Shijiazhuang Pro-Gear Trading Co., Ltd.|360-Degree Visibility&Phosphorescent Reflective Material

NewsSep.02,2025

-

Outdoor Dog Coat with Reflective-Shijiazhuang Pro-Gear Trading Co., Ltd.|Reflective Safety&Comfort

NewsSep.02,2025

-

Outdoor Dog Coat with Reflective Technology-SHJZ Pro-Gear

NewsSep.02,2025

-

Outdoor Dog Coat with Reflective - Shijiazhuang Pro-Gear Co.

NewsSep.02,2025

-

Pet Apparel Safety Gear- Shijiazhuang Pro-Gear Trading Co., Ltd.|Reflective Technology&Comfort

NewsSep.02,2025

-

Pet Apparel Safety Gear Outdoor Dog Coat With Reflective-Shijiazhuang Pro-Gear Trading Co., Ltd.|Reflective Safety Technology, Comfortable Design

NewsSep.02,2025