Aug . 06, 2025 02:20 Back to list

Durable Kid Outdoor Pants for Dog Train Suppliers

Market Evolution: The Rising Demand for Specialized Youth Outdoor Apparel

The landscape of children's outdoor apparel has transformed dramatically. Gone are the days of generic, ill-fitting clothing. Today's market, driven by a surge in family outdoor activities like hiking, camping, and dog training, demands specialized gear that mirrors the performance of adult apparel. According to a recent Global Industry Analysts Inc. (GIA) report, the global children's wear market is projected to reach US$297.8 Billion by 2026. A significant portion of this growth is attributed to the performance and outdoor segments. Parents and training organizations are no longer just looking for clothing; they are investing in safety, durability, and comfort.

This trend places immense focus on the capabilities of a kid outdoor pants for dog train suppliers. The ability to produce pants that withstand abrasion, repel water, offer breathability, and incorporate safety features like high-visibility elements is paramount. As a leading kid outdoor pants for dog train manufacturer, we observe a clear market pivot towards technical fabrics like Ripstop and Cordura, ergonomic designs that allow for a full range of motion, and sustainable manufacturing practices certified by standards like OEKO-TEX®.

Deconstructing Excellence: The Manufacturing Process of a Premier Kid Outdoor Pants for Dog Train Factory

Understanding the journey from raw material to finished product is crucial when selecting a supplier. A truly professional kid outdoor pants for dog train factories network relies on a meticulous, technology-driven process that guarantees consistency, durability, and performance. Here at Clawfort, we adhere to a stringent, multi-stage manufacturing protocol that meets and exceeds ISO 9001 quality management standards.

Step 1: Material Sourcing & In-depth Inspection

Details: We source high-performance textiles like 4-way stretch Ripstop Nylon and Polyester blends. Each batch undergoes rigorous testing for tensile strength (ASTM D5034), water repellency (AATCC 22), and colorfastness (ISO 105) before being accepted into our production line.

Step 2: CAD Pattern Design & Digital Prototyping

Details: Our engineers use advanced CAD software to create precise, ergonomic patterns. This digital approach minimizes material waste and allows for complex designs with articulated knees and gusseted crotches for maximum mobility—essential for active kids during dog training.

Step 3: Automated CNC Fabric Cutting

Details: Patterns are sent to computer-numerical-control (CNC) laser cutting machines. This ensures every panel is cut with sub-millimeter accuracy, a feat impossible with manual methods. This precision is key to a perfect fit and durable seam construction.

Step 4: Precision Stitching & Assembly

Details: Skilled technicians use industrial sewing machines to assemble the garments. We utilize high-strength nylon thread and employ techniques like double-stitching and bar-tacking on stress points (pocket corners, belt loops) to ensure a product lifespan that withstands rigorous use.

Step 5: Seam Sealing & Feature Integration

Details: For waterproof models, critical seams are sealed with thermal tape to prevent water ingress. Zippers (YKK® as standard), reflective trims (3M™ Scotchlite™), adjustable waistbands, and other custom features are integrated at this stage.

Step 6: Final Quality Control & ISO 9001 Compliance Check

Details: Every finished pair of pants undergoes a multi-point inspection. We check for seam integrity, feature functionality, and cosmetic perfection. This final check ensures that every product shipped by our kid outdoor pants for dog train supplier division meets our "zero defect" policy.

Supplier Landscape: A Comparative Analysis

Choosing the right kid outdoor pants for dog train suppliers is a critical business decision. The market includes a wide range of manufacturers, from small workshops to large-scale industrial factories. To aid in your decision-making, we've compiled a comparison table that highlights key performance indicators. This transparency demonstrates our commitment to being a top-tier kid outdoor pants for dog train manufacturer.

| Feature / Capability | Clawfort (Premier Supplier) | Standard Generic Supplier | Low-Cost Alternative |

|---|---|---|---|

| Material Sourcing | Premium, certified technical fabrics (e.g., Ripstop, Softshell) with documented specifications. | Standard, non-certified polyester/nylon blends. | Often uses fabric overstocks with inconsistent quality. |

| Certifications | ISO 9001, OEKO-TEX® Standard 100, BSCI Audited. | May have basic local certifications. | Usually uncertified. |

| Manufacturing Tech | CAD design, CNC cutting, automated sewing, seam sealing. | Manual cutting, standard sewing machines. | Primarily manual and outdated processes. |

| Customization (OEM/ODM) | Full customization: fabric, color (Pantone match), logo, features, fit. | Limited to logo application and pre-set color options. | Minimal to no customization available. |

| Minimum Order Quantity (MOQ) | Flexible, typically 300-500 pcs per style/color. | Often rigid, 1000+ pcs. | Varies, but quality control is a risk at low volumes. |

| Quality Control | Multi-stage inspection, AQL 2.5 standard, third-party testing available. | Final product visual check only. | Inconsistent or non-existent QC. |

| Lead Time | 45-60 days after sample approval. | 60-90 days, often with delays. | Unpredictable. |

| Product Lifespan (Est.) | 3-5+ years of regular use. | 1-2 seasons of use. | Less than one season. |

Application Scenarios & Technical Advantages

The true test of outdoor gear is its performance in the field. Our products are engineered not just for one specific task, but for a multitude of environments where kids and their canine companions explore.

Key Application Scenarios:

- Canine Agility Training: The pants' 4-way stretch fabric and articulated knees allow for unrestricted movement when running, squatting, and guiding a dog through an agility course.

- Search and Rescue Training: Reinforced knee and seat panels made from abrasion-resistant Cordura® fabric protect against rough terrain, branches, and rocks.

- All-Weather Hiking: A DWR (Durable Water Repellent) finish coupled with high breathability keeps kids dry and comfortable, preventing chilling from sweat or light rain.

- General Outdoor Play: The tear-resistant nature of Ripstop fabric means the pants can withstand the rigors of climbing, crawling, and everyday adventures.

These scenarios highlight the technical advantages provided by a superior kid outdoor pants for dog train supplier. Our focus on material science and ergonomic design directly translates to enhanced safety, comfort, and longevity of the garment.

Beyond Human Apparel: Expertise in High-Performance Gear for All

While our expertise as a premier kid outdoor pants for dog train factory is well-established, our engineering and manufacturing capabilities extend across the entire spectrum of performance outdoor gear. This holistic approach allows us to apply material science and design principles universally, benefiting both human and animal athletes. A prime example of this cross-disciplinary excellence is our highly-acclaimed canine apparel line, which includes products sought after by leading retailers like PetSmart.

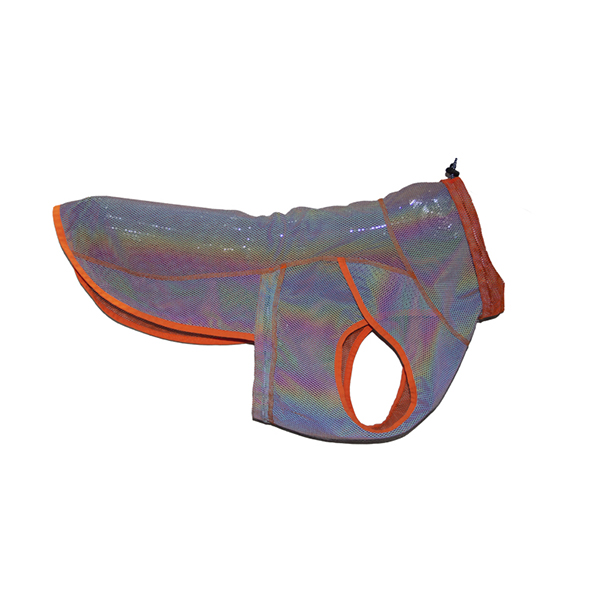

Featured Product: Dog Apparel Dog Summer Jacket Reflective

This jacket exemplifies our commitment to quality. Just as we engineer kids' pants for durability and comfort, we design this jacket for canine safety and thermal regulation. It's a testament to the fact that a skilled manufacturer, whether labeled a dog vest petsmart suppliers or a kids' apparel factory, focuses on the core principles of performance. The same QC standards, material testing, and design philosophy are applied across all product lines.

Product Link: Dog Apparel Dog summer jacket reflective

Performance Comparison: Clawfort vs. Generic

Jacket Material Composition

Cooling Efficiency Over Time

Customization Solutions (OEM/ODM)

Your brand is unique. Your products should be too. As a client-focused kid outdoor pants for dog train manufacturers network, we offer comprehensive Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services. This allows you to create a product that is perfectly aligned with your brand identity and target market.

Our Customization Capabilities:

- Material Selection: Choose from our extensive library of technical fabrics or specify a custom-sourced material.

- Color & Dyeing: We offer precise Pantone® color matching for brand consistency.

- Logo & Branding: Options include high-density screen printing, intricate embroidery, custom zipper pulls, and branded patches.

- Fit & Sizing: Provide your own sizing charts or work with our designers to develop a custom fit for your target demographic.

- Feature Modification: Add or remove pockets, specify zipper types, integrate reinforced patches, or request unique ventilation systems.

- Packaging & Labeling: We can design and produce custom hang-tags, labels, and packaging to create a retail-ready product.

Case Study: Partnering with "Trail Pups" Youth Academy

The Challenge

The "Trail Pups" Youth Academy, a non-profit organization teaching kids responsible dog handling and outdoor skills, was facing equipment failure. Standard children's pants were tearing within weeks, leading to high replacement costs and safety concerns. They needed a durable, safe, and affordable solution.

The Solution

Trail Pups collaborated with Clawfort, a leading kid outdoor pants for dog train suppliers. Through our ODM program, we designed a custom pant specifically for their needs. Key features included:

- A base fabric of 220gsm Polyester/Spandex Ripstop for durability and flexibility.

- Reinforced knee and seat panels using 500D Cordura® fabric.

- Integrated 3M™ reflective piping along the side seams for high visibility in low light.

- An adjustable elastic waistband to accommodate growing kids.

- The Trail Pups logo embroidered on the cargo pocket.

The Outcome

The custom pants were a resounding success. Garment failure rates dropped by over 95% in the first year. The academy could reallocate funds from clothing replacement to program expansion. Parents reported higher satisfaction and felt their children were safer.

"Working with Clawfort transformed our program. They didn't just sell us a product; they provided a solution. The quality and thoughtfulness that went into the design were evident from day one. They are more than a kid outdoor pants for dog train factory; they are a true partner in our mission."

Building Trust: Our Commitments & Guarantees

Trust is the cornerstone of any successful partnership. We build it through transparency, reliability, and an unwavering commitment to quality. When you choose us as your kid outdoor pants for dog train manufacturer, you are choosing a partner dedicated to your success.

Our Promises to You:

Delivery & Logistics

We provide clear and realistic production timelines from the moment your order is confirmed. Our standard lead time is 45-60 days post-sample approval. We partner with reliable global freight forwarders (DHL, FedEx, Sea Freight) to ensure timely and secure delivery to your doorstep, with full tracking provided.

Quality Warranty

We stand by our craftsmanship. All our products come with a 12-month manufacturer's warranty against defects in materials and workmanship. Should any product fail to meet our stringent quality standards, we offer a hassle-free replacement or credit policy.

Dedicated Customer Support

Each client is assigned a dedicated account manager who serves as your single point of contact. From initial inquiry to post-delivery support, your manager is available to answer questions, provide updates, and resolve any issues swiftly. Our support team is fluent in multiple languages to facilitate clear communication.

Frequently Asked Questions (FAQ)

Ripstop fabric is a woven material, often made of nylon or polyester, that uses a special reinforcing technique to make it resistant to tearing and ripping. During weaving, thicker reinforcement threads are interwoven at regular intervals in a crosshatch pattern. This grid-like structure prevents a small tear from spreading. For active kids, this is a critical feature that dramatically increases the garment's lifespan and durability, making it a key material for any quality kid outdoor pants for dog train supplier.

OEKO-TEX® Standard 100 is a globally recognized, independent testing and certification system for raw, semi-finished, and finished textile products. If a product carries this label, it means every component—from the thread to the fabric to the buttons and zippers—has been tested for harmful substances and is certified safe for human health. For children's apparel, this is a non-negotiable mark of trust and safety, confirming that a kid outdoor pants for dog train manufacturer is committed to producing non-toxic, skin-friendly garments.

We ensure colorfastness through a multi-pronged approach. First, we use high-quality, reactive dyes that form a covalent bond with the fabric fibers, making them highly resistant to fading. Second, every custom-dyed batch undergoes rigorous testing based on ISO 105 standards, which assess colorfastness to washing, light, and crocking (rubbing). This ensures the colors remain vibrant and do not bleed, even after repeated use and laundering.

Water-resistant fabric is tightly woven and/or treated with a Durable Water Repellent (DWR) finish, causing water to bead up and roll off. It can handle light rain or splashes for a short period. Waterproof fabric provides a complete barrier to water. This is achieved either through a membrane (like Gore-Tex®) laminated to the fabric or a coating. For true waterproof performance, the seams must also be sealed with tape. We offer both options depending on the intended use and budget of the client.

Our MOQ is designed to be flexible to support both emerging brands and established enterprises. Typically, our MOQ starts at 300-500 pieces per style and color. However, we encourage you to discuss your specific needs with our team. For certain projects, we can explore smaller batch options. This flexibility is a key advantage of working directly with a customer-centric kid outdoor pants for dog train factory.

Absolutely. Safety is a top priority, especially for children's wear. We are proficient in integrating a variety of safety enhancements. We commonly use 3M™ Scotchlite™ reflective materials, which meet high international visibility standards (like EN ISO 20471). These can be applied as piping, patches, or full panels to ensure children are easily seen by others in low-light conditions during evening dog training or hiking.

An 'articulated knee' is a design feature where the pattern is cut and sewn with pre-bent darts or extra panels around the knee area. This mimics the natural bend of the leg, preventing the fabric from pulling tight when squatting, kneeling, or running. It significantly improves ergonomic comfort and freedom of movement, a critical feature for high-activity apparel and a hallmark of a sophisticated kid outdoor pants for dog train manufacturers design process.

References & Further Reading

- "Technical Textiles in Sportswear: A Comprehensive Review." Journal of Industrial Textiles, vol. 51, no. 2, 2022, pp. 154-178. https://journals.sagepub.com/home/jit

- "Trends in Sustainable and Performance Apparel Manufacturing." Textile World, 15 May 2023. https://www.textileworld.com/

- "The Psychology of Color in Branding and Product Design." Outdoor Retailer Magazine - Industry Forum, Winter 2023. https://www.outdoorretailer.com/

-

Pet Apparel Safety Gear - Shijiazhuang Pro-Gear Trading Co., Ltd.|360-Degree Visibility&Phosphorescent Reflective Material

NewsSep.02,2025

-

Outdoor Dog Coat with Reflective-Shijiazhuang Pro-Gear Trading Co., Ltd.|Reflective Safety&Comfort

NewsSep.02,2025

-

Outdoor Dog Coat with Reflective Technology-SHJZ Pro-Gear

NewsSep.02,2025

-

Outdoor Dog Coat with Reflective - Shijiazhuang Pro-Gear Co.

NewsSep.02,2025

-

Pet Apparel Safety Gear- Shijiazhuang Pro-Gear Trading Co., Ltd.|Reflective Technology&Comfort

NewsSep.02,2025

-

Pet Apparel Safety Gear Outdoor Dog Coat With Reflective-Shijiazhuang Pro-Gear Trading Co., Ltd.|Reflective Safety Technology, Comfortable Design

NewsSep.02,2025